Applications

PUMP PROTECTION

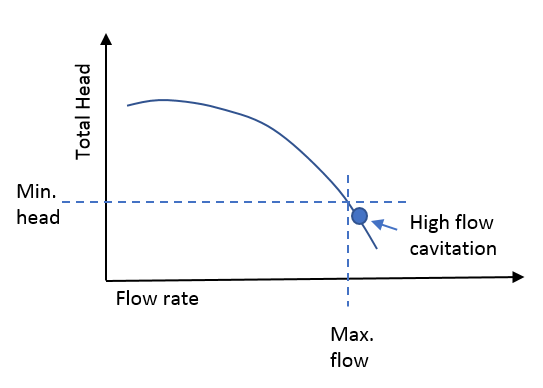

Protecting valuable pump equipment and ensuring they work at the highest efficiency, with the bare minimum of unplanned downtime is essential. Maric Flow Control Valves can help by ensuring there is an adequate “head” or discharge pressure on the pump, which can be pre-set to manufacturer’s design specifications to avoid cavitation or bearing damage. These brilliantly simple valves automatically deliver a fixed pre-set and constant flow of water, irrespective of pressure differentials between upstream and downstream within the range of 140-1000 kPa. Valves are customized to your flow rate

Beneficial applications for pump protection

- Reduces warranty claims for centrifugal pumps

As pumps are often damaged when a throttling gate-vale is unwittingly opened up, which creates too high flow rate.

- Limiting peak flow rates

Helps maintain adequate water is availabe at the suction and avoids flow rates that are too high to be efficient.

- Ensuring there is always head or discharge pressure on the pump

By pre-setting the flow to meet the manufacturer’s design specifications.

- Preventing unauthorised adjustments

Ensuring that the flow-rate can never exceed manufacturer’s intended rate.

- Constant flow of gland flushing water (packing or seal water)

Regardless of gland water pressure, slurry pump discharge pressure or condition of the gland.

- Extend gland life

Fixing flow-rates to maximise the life of the gland.

- Conserving water

Controlling flow to pump glands to reduce valuable packing water supplies.

- Limiting the dilution of slurry or product

By controlling the flow of water over the gland.

Benefits of Maric Flow Control valves

- Valve automatically responds instantly to pressure fluctuations

- No external actuation required

- Self-cleaning and maintenance-free design

- Extremely compact compared to conventional diaphragm valves

- Lifespan of up to 15+ years

- Tamper-proof, preventing unauthorised adjustments

- Odour-free and non-toxic

Tailoring solutions to your specifications

Akro Valve offer a wide range of flow control solutions, our technical experts will guide you through the process of selecting the right connection types, sizes, and materials. we can also modify our basic valve design to create equipment that meets your specific site requirements.

Pipes, valves and fittings for every project

Akro Valve offer a range of pipe fittings and tools for the repair and maintenance of water and fluids installations. We can supply pipes, fittings and tools to your requirements.

How can we help? Contact us to discuss your requirements 01323 485272

Related Project

Maintaining constant flow at a legendary distillery

How we helped maintain a constant flow of craft beer into whiskey barrels during the finishing process of a wolrd famous whiskey.