Maric Flow Control Rubbers

Maric Flow Control rubber is at the heart of the flow control valve, the diameter of the rubber orifice responds automatically to pressure fluctuations, adjusting to maintain a constant flow rate. As pressure differential increases, the orifice diameter reduces to maintain the pre-set flow rate. Likewise, as pressure reduces the orifice automatically opens up to maintain the pre-set, constant flow rate, regardless of pressure variations.

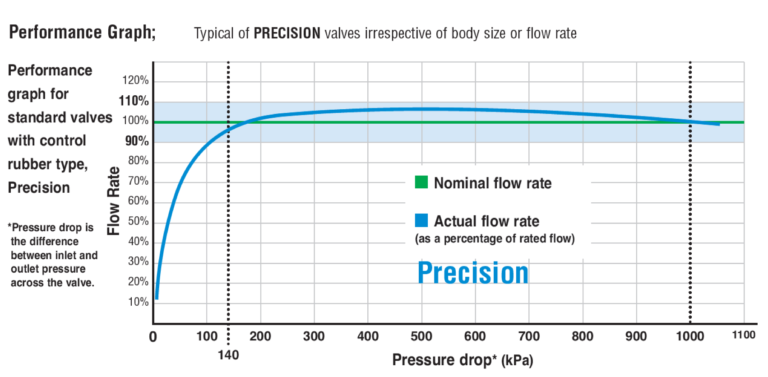

Akro valve uses precision nitrile control rubbers, fitted as standard, unless otherwise requested. Precision rubbers offer the best flow rate accuracy and tolerate a wide range of chemical environments. This makes them suitable for most mains pressure, pumping, industrial and water treatment applications.

Factors to consider when selecting alternative control rubbers for the valves include:

- Maximum pressure differential

- Compatibility with chemical environment

- Operating temperature

- Noise

- Body material compatibility

Should installation parameters render Precision rubbers unsuitable, then the chart below provides the specifications for the full range of control rubbers available.

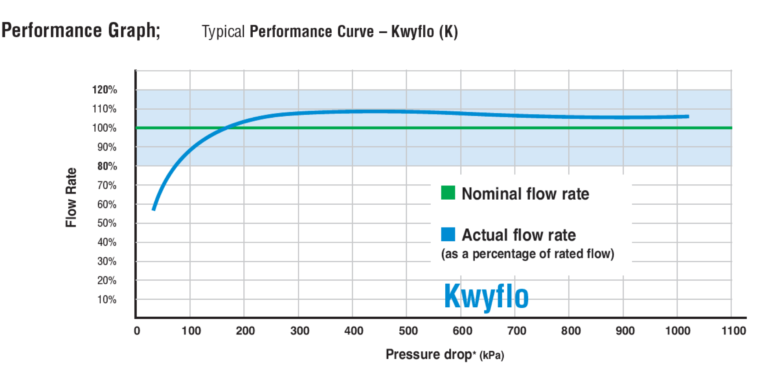

For quiet valve operation we recommend the Kwyflo control rubber type.

Technical Data

Rubber Type | Code | Rubber Material | Pressure Differential Range | Flow Accuracy | Max Temp. | Applications |

|---|---|---|---|---|---|---|

Precision | PR | Nitrile | 1.4 - 10 Bar (20-150psi) | +/-10% | 60C | Best flow rate accuracy and tolerate a wide range of chemical environments, making them suitable for most mains pressure, pumping, industrial and water treatments. This is product complies with "WaterMark" licence and AS4020 Potable water requirement. |

Kwyflo | KY | Nitrile | 1.4 - 10 bar (20 - 150psi) | +/-20% | 60C | Where noise must be minimised. Not suitable for Stainless Steel valve bodies. |

Spotcheck | SC | Nitrile | 1.4 - 10 bar (20 - 150psi) | +/-20% | 60C | Receive less than 100% performance testing and may not deliver +/-10% flow rate accuracy. |

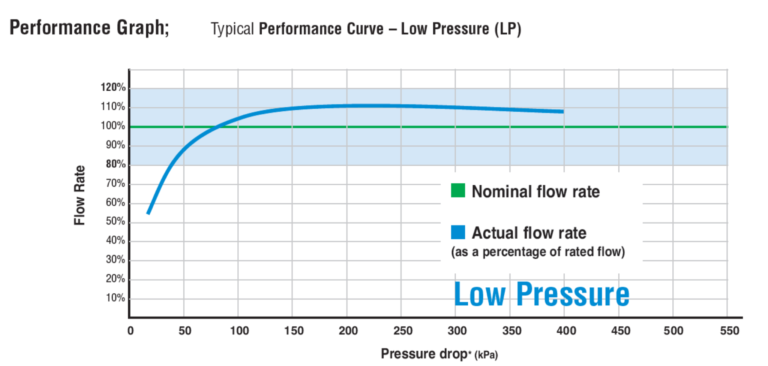

Low Pressure | LP | Nitrile | 0.4 - 10 bar (6 - 30psi) | +/-20% | 60C | Used where the installation demands a low headloss flow controller. Flow rate available from 5LPM. |

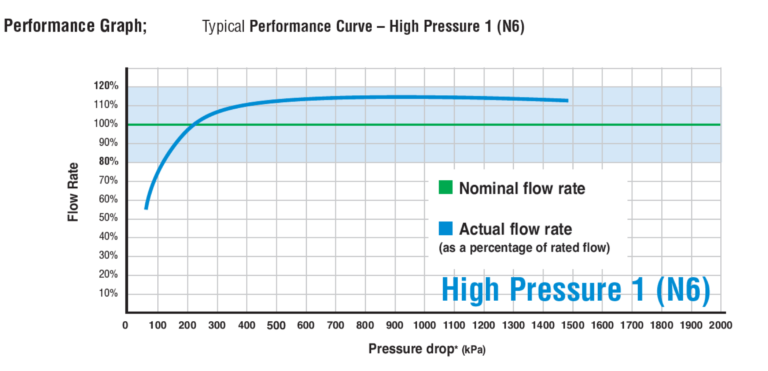

High Pressure 1 | N6 | Nitrile | 1.4 - 15 bar (20 - 215psi) | +/-20% | 60C | Used where installation pressures exceed that which Precision valves will handle. Not compatible with PVC bodies. |

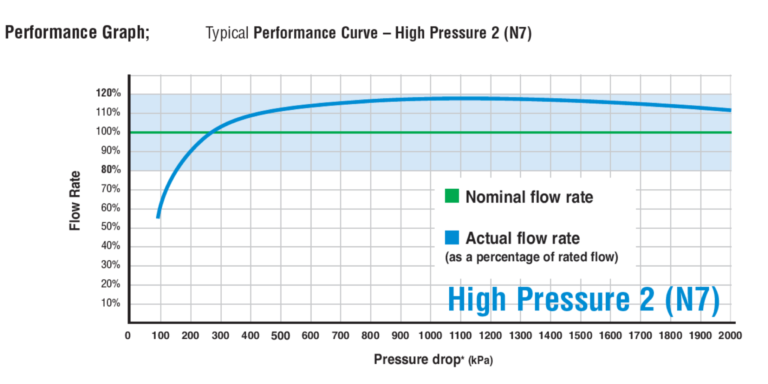

High Pressure 2 | N7 | Nitrile | 1.7 - 20 bar (25 - 290psi) | +/-20% | 60C | Used where installation pressures exceed that which Precision and High Pressure 1 valves will handle. Compatible with Stainless Steel bodies only. |

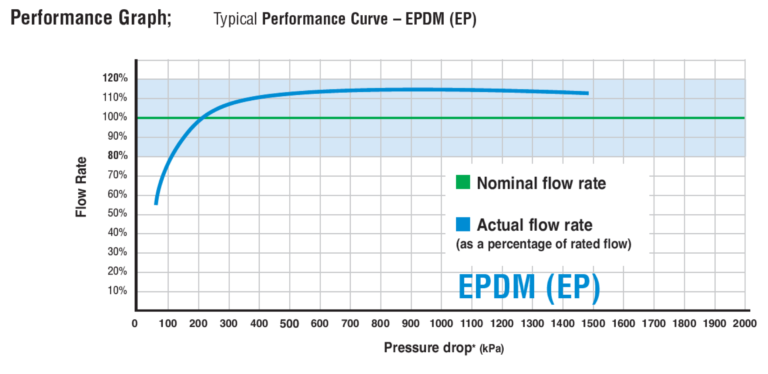

EPDM | EP | EPDM | 1.4 - 15 bar (20 - 215psi) | +/-20% | 100C | For handling higher temperatures and pressures that standard Precision nitrile. Also suitable in a caustic environment which makes them ideal for the alumina industry. |

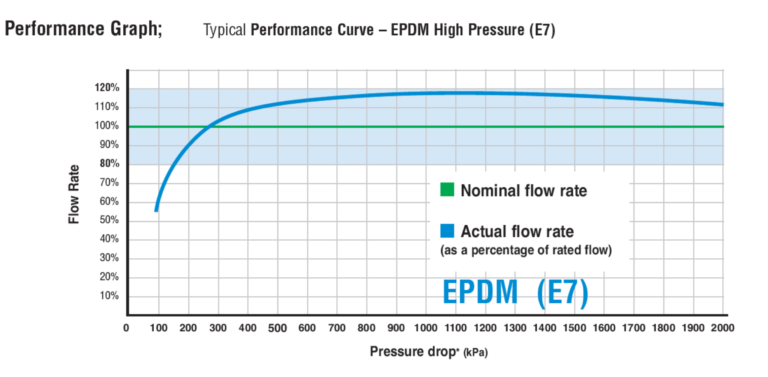

EPDM High Pressure | E7 | EPDM | 1.7 - 20 bar (25 - 290psi) | +/-20% | 100C | For handling higher temperatures and pressures that standard nitrile and EPDM. Also suitable in caustic environment which makes them ideal for alumina industry. Compatible with Stainless Steel bodies. |

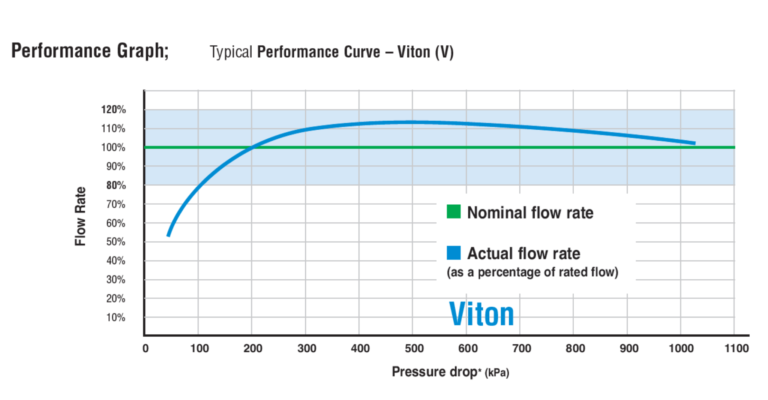

Viton | VT | Viton | 1.4 - 10 bar (20 - 150psi) | +/-20% | 200C | For where temperatures above 100 degrees Celsius and below 200 degrees Celsius are encountered. Also the preferred material in chemical environments where both Nitrile or EPDM control rubbers are unsuitable. |